10 August, 2023

Are You Looking For a

Web Devlopement | App Devlopement

3D Printing: An innovation in Manufacturing

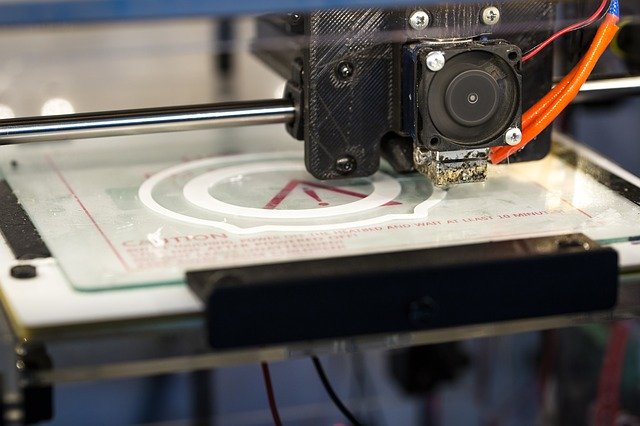

Overview 3D printing is sometimes referred to as Additive Manufacturing (AM). In 3D printing, one creates a design of an object using the software, and the 3D printer creates the object by adding layer upon layer of material until the shape of the object is formed. The item can be made with several printing materials, for example, plastics, powders, filaments, and paper. Many countries across the world are investing heavily in this technology. this shall soon become a commonplace a common household item. What is 3D Printing? 3D additive or printing manufacturing is now a procedure for making 3d solid objects out of a digital document. The making of a 3d-printed item is achieved using additive procedures. Within an additive procedure, An item is made by placing down consecutive layers of material before the item is established 3D Printing may be your alternative to subtractive manufacturing by which individuals are able to remove material to make an object. How does it Work? There are 3 main steps in 3D printing:- First-step:- Step one is the preparation right before printing while you design a 3D file of the item that you need to print. This 3D file could be created with CAD software, with a 3D scanner or even normally downloaded via an internet marketplace. Once you've assessed your 3D document is about to be printed, you are able to move into the next step. Second-step:- The next step is the printing procedure. To begin with, you have to select which material will achieve the particular properties required for the object. The wide range of substances utilized in 3D printing is very broad. It includes plastics, ceramics, resins, metals, sand, textiles, biomaterials, food, glass as well as rain dust! The majority of these substances also enable many finishing options that allow you to get the particular design result you had in mind, and also a few others, for example, glass, by way of instance, continue to be manufactured since 3D printing stuff and aren't easily accessible yet. Third-step:- The next step is your completing process. This step needs special skills and substances. while the item is first printed, usually it can't be used or delivered before it's been sanded, lacquered or painted to accomplish it as planned. The material chosen for the plan can determine which printing techniques will be suitable. Software Uses in 3D printing There are several unique 3D modeling software tools out there. Industrial tier software can cost tens of thousands per year each license, however, additionally, there is opensource software you may buy at no cost. We frequently urge beginners to begin using Tinkercad. Tinkercad is absolutely free and works on your browser, that you do not need to set it up on your PC. Tinkercad offers newcomer lessons and also has an integrated feature to receive your 3D version printed using 3d-print services. Now you own a 3D version, another thing to do is to organize the document for the 3D printer. This is known as slicing. Some important examples of 3D Printing 3D printing encompasses various types of technologies and substances because 3D printing is used in almost all businesses you can consider. It is critical to view it as a bunch of diverse businesses with an assortment of unique software. A Couple of examples: Dental goods Eye-wear architectural scale versions & maquettes prosthetics film props layout (lamps, furniture, and so on ) reconstructing fossils from paleontology replicating historical artifacts from archaeology reconstructing body and bones components in forensic pathology reconstructing deeply ruined signs recovered from a crime scene Conclusion:- The list of 3D printing technologies and processes continues to grow as 3D printing is always changing. The 3D printing industry continues to innovate its hardware as well as the materials and processes to create objects or parts. Depending on many factors such as budget, design or function, choosing the appropriate 3D printing process as well as the right material is important. 3D printing could make a variety of 3d-printed items that were formerly only manufactured through mass manufacturing procedures. An online 3D printing service such as Sculpteo is because of this complexity, time and techniques required for your printing and finishing steps. This complexity may hinder people from using this wonderful technology, but at Sculpteo we apply our knowledge to serve anyone willing to try 3D printing, as we want to broaden access to additive manufacturing technology.

.jpg)